Revolutionizing Energy Storage with Plasma-Created Silicon

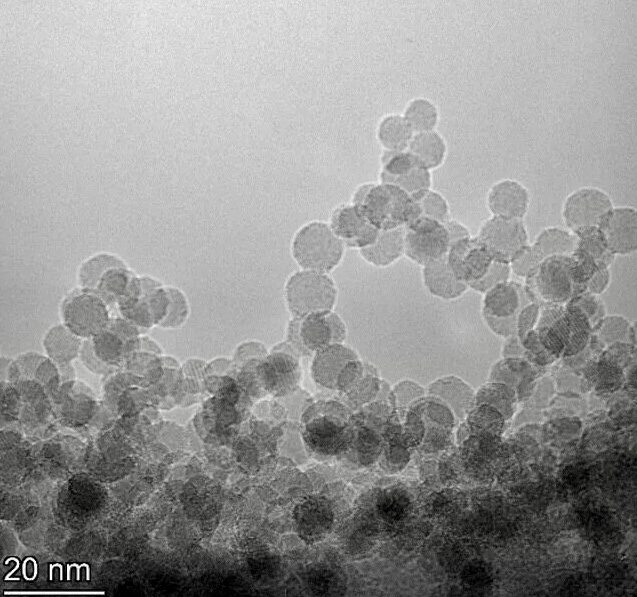

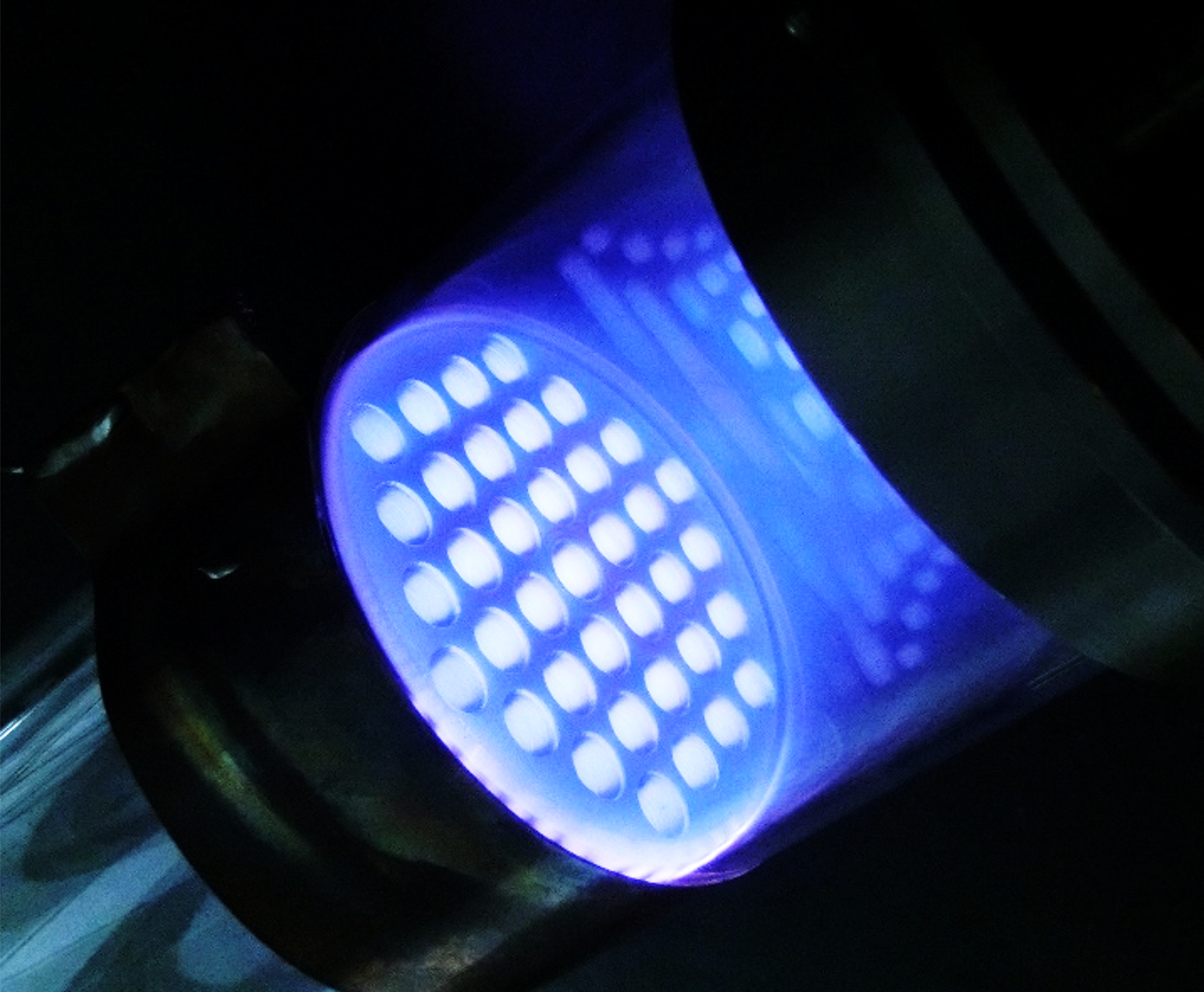

Our core innovation is a patented, room-temperature plasma process that converts silane gas into ultra-small silicon particles (<10 nm) with nearly 100% conversion efficiency in a matter of milliseconds. These ultra-small particles eliminate the swelling and cracking issues of silicon and enable vastly superior performance compared to commercial silicon powders. Our ultra-fast production reduces costs and maximizes silane utilization.

Our scalable manufacturing approach has been industrially demonstrated in the photovoltaic and semiconductor industries with low capital requirements. Additionally, the drop-in readiness of our silicon ensures that we can meet the demands of any industry, from electric vehicles to drones, without significant capital investment or infrastructure changes for cell manufacturers worldwide.

Our plasma technology stems from nearly a decade of research by Professor Lorenzo Mangolini’s group at the University of California, Riverside, and the University of Minnesota. After extensive R&D and testing of almost every commercial silicon powder available, we have confirmed and third-party validated that our plasma-produced silicon not only outperforms others but also scales more easily. Professor Lorenzo Mangolini is the original inventor of this plasma process.

In addition to the high performance, our silicon is also drop-in ready.

We achieve this by coating the ultra-small silicon particles with a graphitic carbon shell with our patented, low-temperature CVD step.

This step makes our silicon resemble graphite’s shape, size, and density, and makes it fully compatible with water slurries and roll-to-roll manufacturing, ensuring seamless integration adoption for any cell manufacturer. [1]

[1] Nava, G., Schwan, J., Boebinger, M. G., McDowell, M. T., & Mangolini, L. (2019). Silicon-Core–Carbon-Shell Nanoparticles for Lithium-Ion Batteries: Rational Comparison between Amorphous and Graphitic Carbon Coatings. Nano Letters, 19(10), 7236-7245. doi:10.1021/acs.nanolett.9b02835

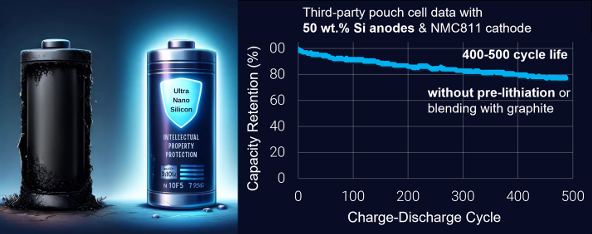

Our silicon has been rigorously tested in pouch-size full cells by renowned industry labs such as SpectraPower, Polaris Battery Labs, and the Michigan Battery Lab. The results speak for themselves:

Achieve significantly higher energy density with our silicon-dominant anode material compared to traditional graphite-based batteries.

Our ultra-fast, room-temperature plasma process produces high-quality silicon powders at significantly lower costs and capital investment.

No need for pre-lithiation, pre-cycling, pressurization, or graphite blends—our material integrates seamlessly into existing cell manufacturing pipelines.

Our plasma process generates minimal waste, converting almost all precursors into usable battery materials. This process has minimal to no emissions, with hydrogen as the only by-product, and uses abundant materials like silicon and carbon.

Tested by leading industry labs, our silicon anode material has demonstrated exceptional cycle life, energy density, and cycle life without requiring complex and expensive protocols.

Our silicon works with any cathode, electrolyte, or format - enabling a universal silicon solution for all cell manufacturers.

At 4th State Energies, our plasma-created silicon anode technology offers unparalleled advantages that set us apart from first-generation silicon solutino. From enhancing battery performance to lowering production costs and minimizing environmental impact, here’s why our technology is the future of energy storage:

At 4th State Energies, we are on a mission to revolutionize

the energy storage industry through cutting-edge, scalable

plasma-created silicon anode technology.

Follow us on LinkedIn: